50 Years Motor Oil

The growth of Motor Oil: Important milestones

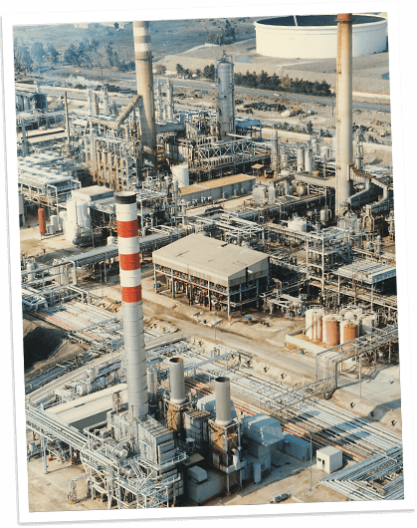

1972

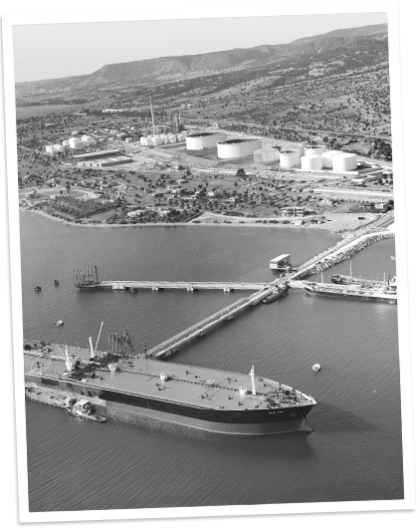

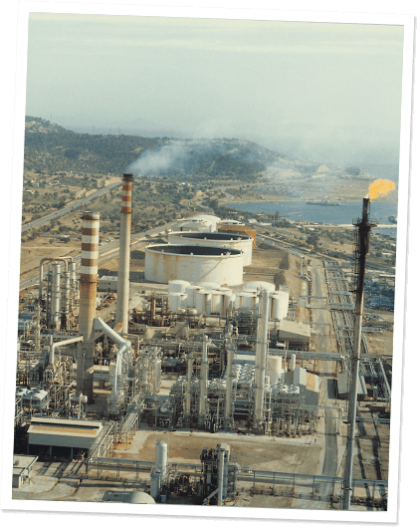

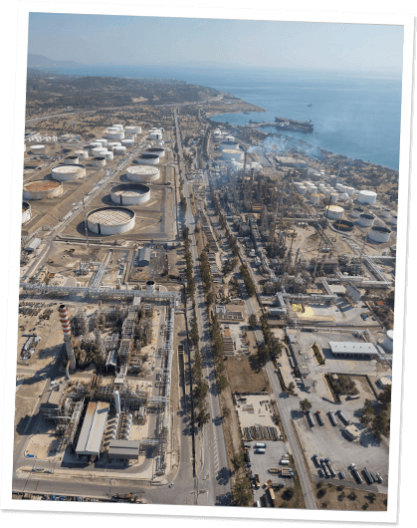

Commissioning of the refinery. It comprises a Crude Oil Distillation Unit, a base oils production unit and port facilities.

1975

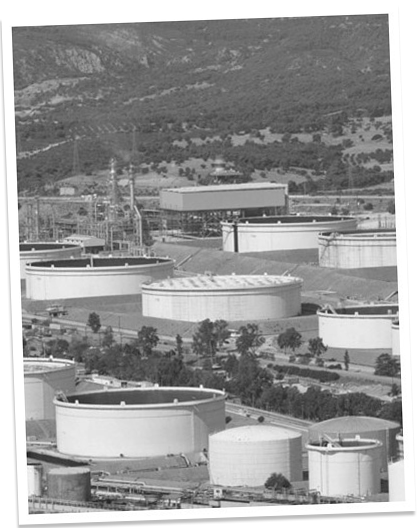

Construction completion of the 100,000 barrels/day Crude Distillation Complex. Construction completion of the 1.5 million cubic metres tank farm.

1978

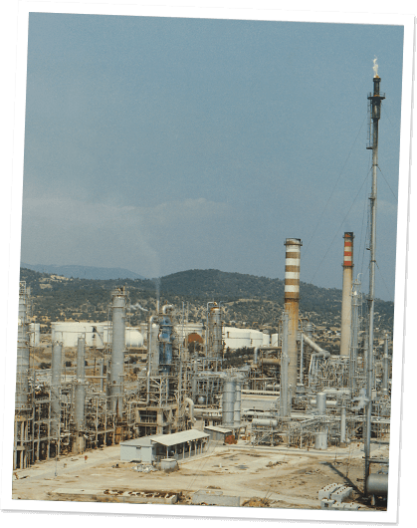

Commissioning of the Catalytic Reformer Unit for gasoline production.

1980

Commissioning of the Catalytic Cracking Unit (for converting fuel oil to higher added value products).

1984

Construction of a Power Plant, burning fuel gas.

1993

ISO 9002 quality certification for the entire range of the company’s commercial and manufacturing activities.

1996

Purchase of 50% of the company’s shares by Saudi Arabian Oil Company (Saudi Aramco). Relocation of the Head Office to a modern Offices Complex in Maroussi.

2000

Construction of new units and upgrading of the Naphtha Reformer into a continuous 103-octane number catalyst regeneration unit for the production of fuels conforming to EU specifications.

New Central Control Room and installation of a Distributed Control System.

Certification of the Environmental Management System, according to ISO 14001:1996.

2001

Increase of the company’s equity capital through public offer of shares and listing on the Athens Stock Exchange. Upgrading of the Lubes Vacuum Distillation Unit.

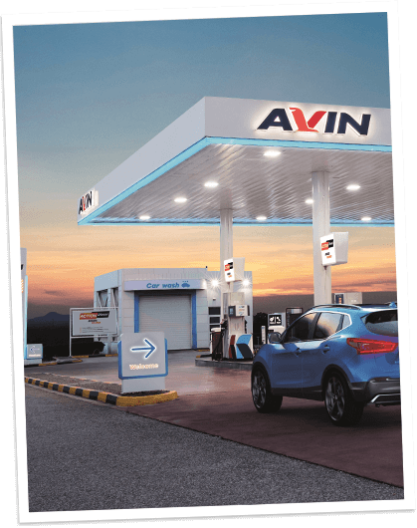

2002

Acquisition of 100% of the retail oil marketing company AVIN OIL.

2004

Commissioning of the new Truck Loading Terminal at the refiner

2005

The Hydrocracker Complex is commissioned, facilitating the production of “clean fuels” conforming to European Union specifications. Repurchase of Saudi Aramco’s stake in the company.

2006

Certification of the refinery’s Chemical Laboratory, according to ISO 17025:2005.

2007

Registration of the company in the Hellenic Register of EMAS (Eco-Management and Audit Scheme). Issue of the first voluntary Environmental Statement, conforming with EU Regulation EMAS ER 761/2001.

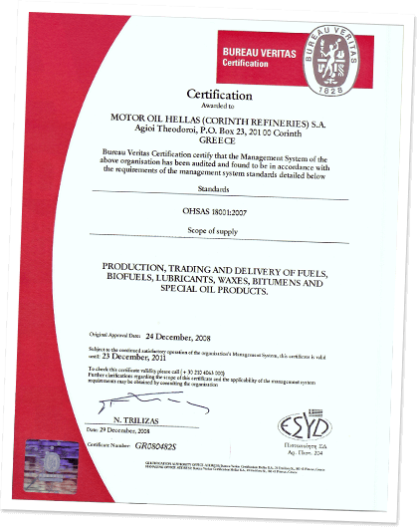

2008

Certification of Health and Safety Management System, according to OHSAS 18001:2007.

2009

Increase of the participation in the share capital of OFC AVIATION FUEL SERVICES S.A. from 28.0% to 92.06%.

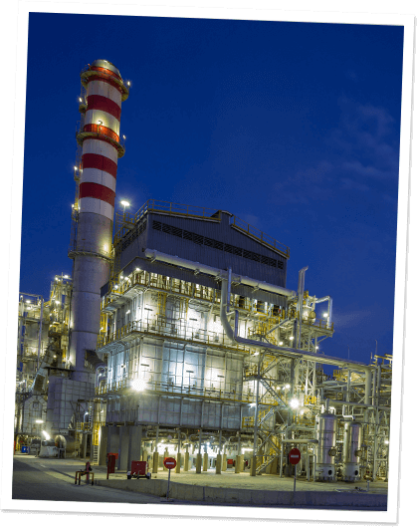

2010

Commissioning of the new 60,000 barrels/day Crude Distillation Unit, and of two additional Sulphur Recovery Units, of a combined 170 ΜΤ/day sulphur production capacity.

Completion of the acquisition of the shares of the companies SHELL HELLAS S.A. (renamed to Coral S.A.), and SHELL GAS A.E.B.E.Y. (renamed to Coral GAS A.E.B.E.Y.), as well as of 49% of the aviation fuels trading company.

2011

Completion of the construction of 5th gas turbine in refinery’s power cogeneration plant, which now has a total capacity of 85MW.

2014

Acquisition of 100% of the retail oil marketing company Cyclon A.B.E.E.

2017

Recertification of the Quality Management System according to the new ISO 9001:2015, of the Environmental Management System according to the new ISO 14001:2015 and of the Health and Safety Management System, according to OHSAS 18001:2007.

Certification of the Motor Oil Refinery according to the ISO 50001:2011 for Energy Management and according to ISO 18788:155 for security.

2018

Acquisition of 90% of the electricity company NRG TRADING HOUSE ENERGY S.A. Rebranding of AVINOIL. Entry into the Serbian retail oil trading market through Coral’s subsidiary, Coral SRB d.o.o Beograd.

2019

Entry of the Motor Oil Group in the Renewable Energy Sources sector through its subsidiary TEFORTO HOLDINGS LTD. Installation of photovoltaic panels at the Refinery.

2020

Start of construction of a new Naphtha processing complex. Increase in the capacity of the Refinery’s Hydrogen production unit. Start of the Digital Transformation Project.

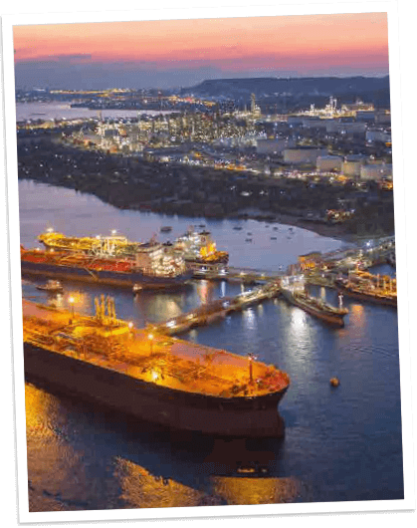

2021

Establishment of the company MORE (Motor Oil Renewable Energy).

Commencement of the construction of a Gas Turbine Combined Cycle Power Plant fuelled by Natural Gas, in Komotini in cooperation with GEK TERNA Group.

Completion of the construction of the new pier at the Refinery.

Installation of a battery energy storage system at the Refinery.

NRG is making the journey of e-mobility a reality by developing an extensive network of fast chargers (incharge) throughout the country.

Entry into the Croatian retail petroleum marketing products, with the acquisition of APIOS D.O.O by Coral S.A. and North Macedonia, through Coral’s subsidiary, Coral Fuels DOOEL Skopje.

2022

Motor Oil and PPC S.A. signed a Memorandum of Understanding for the implementation of projects in the field of green hydrogen.

Acquisition of 29.87% of the shares of Ellaktor Group. Motor Oil Group becomes one of the largest producers of renewable energy. At the same time, MORE will have a portfolio of projects at various stages of development, more than 2.2 GW.

Acquisition of all the shares of ELIN VERD, for investments and activity in the field of renewable and alternative fuels and circular economy.

ΝRG proceeded with the acquisition of 60% of Automotive Solutions, in the field of e-mobility and sustainable micromobility.